ADC, LLC can complete conceptual through detail design and provide completed drawing packages for production of parts through large assemblies and detailed work instructions.

ADC, LLC base drawing package is SOLIDWORKS, which provides the tools to tackle the most complex problems, and the depth and tools to create detailed work quickly.

Generally, analysis is completed during the design phase to help improve the product development process to get your innovative products into production faster.

Drawings and Models can be provided in other formats. Contact ADC, LLC for details.

Classical analysis is often used along with finite element analysis for a quick look at the structural soundness of a design. Below is an example of a loadpath diagram and the classical analysis of the addition of a cargo net to a large aircraft being converted to a cargo plane. Bending, Buckling, and Shear Stress Calculations are all examples of Classical Structural Analysis.

Software such as Matlab, Excel, and custom codes written in Visual Basic or FORTRAN can be used to assist in classical structural analysis.

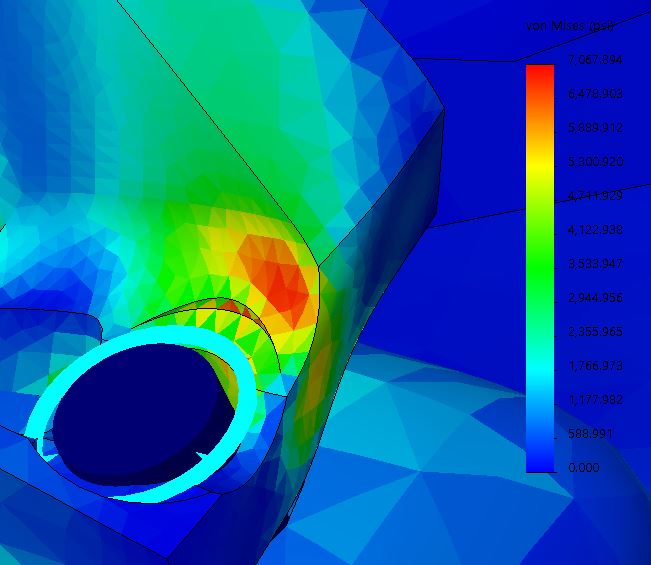

Finite Element Analysis is utilized for stress and modal analysis of components. Initial modal analysis will provide an initial look at the predicted natural frequencies of a component and their mode shapes (How the component will vibrate naturally).

This is often coupled with engineering development testing such as strain gauged vibration testing, ping testing, or laser holography to determine modal damping and allow the analysis to be refined and more load cases be accurately analyzed.

Static or Dynamic Stresses can be obtained from Finite Element Analysis.

Aside from structural and vibration analysis ADC, LLC is also versed in thermal and flow analysis and the design of pumps, accumulators, heat exchangers, valves, other fluid handling components, and in utilizing CFD for the analysis of fluid flow.

Contact ADC, LLC to create an analysis plan that suits your needs.